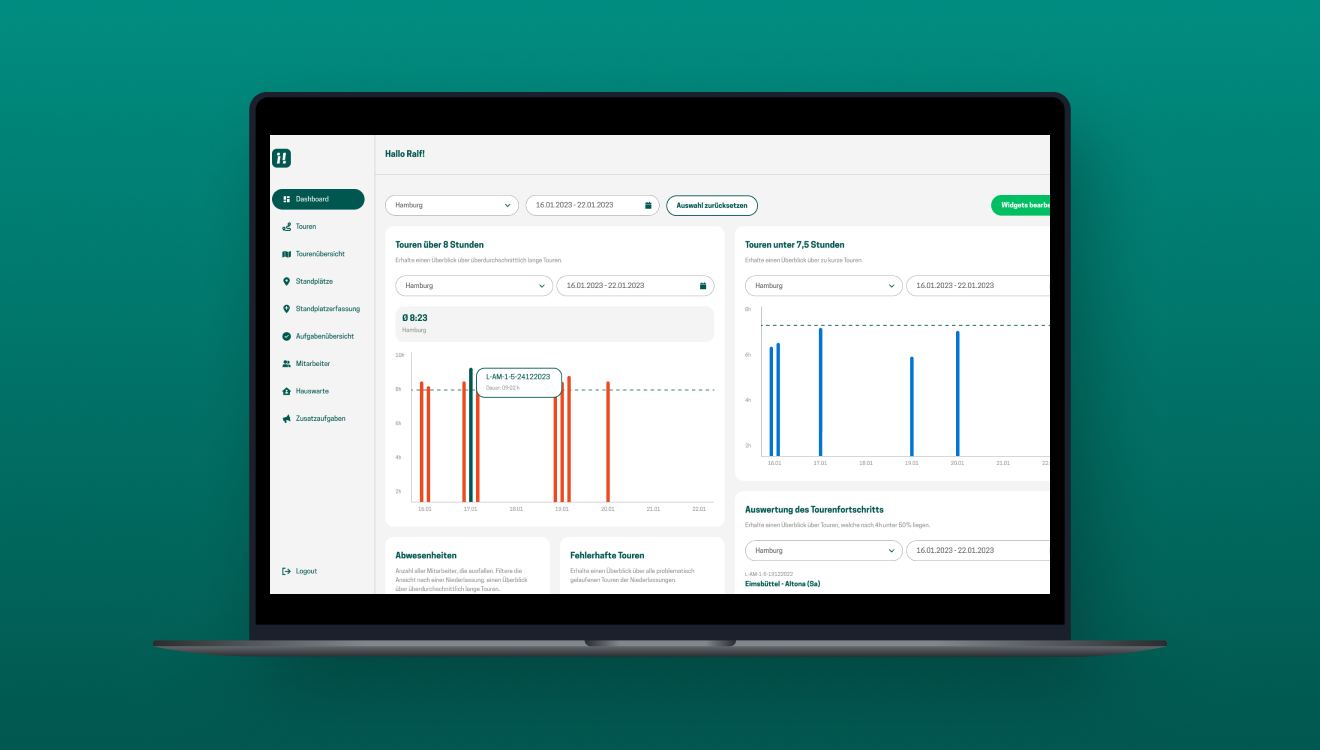

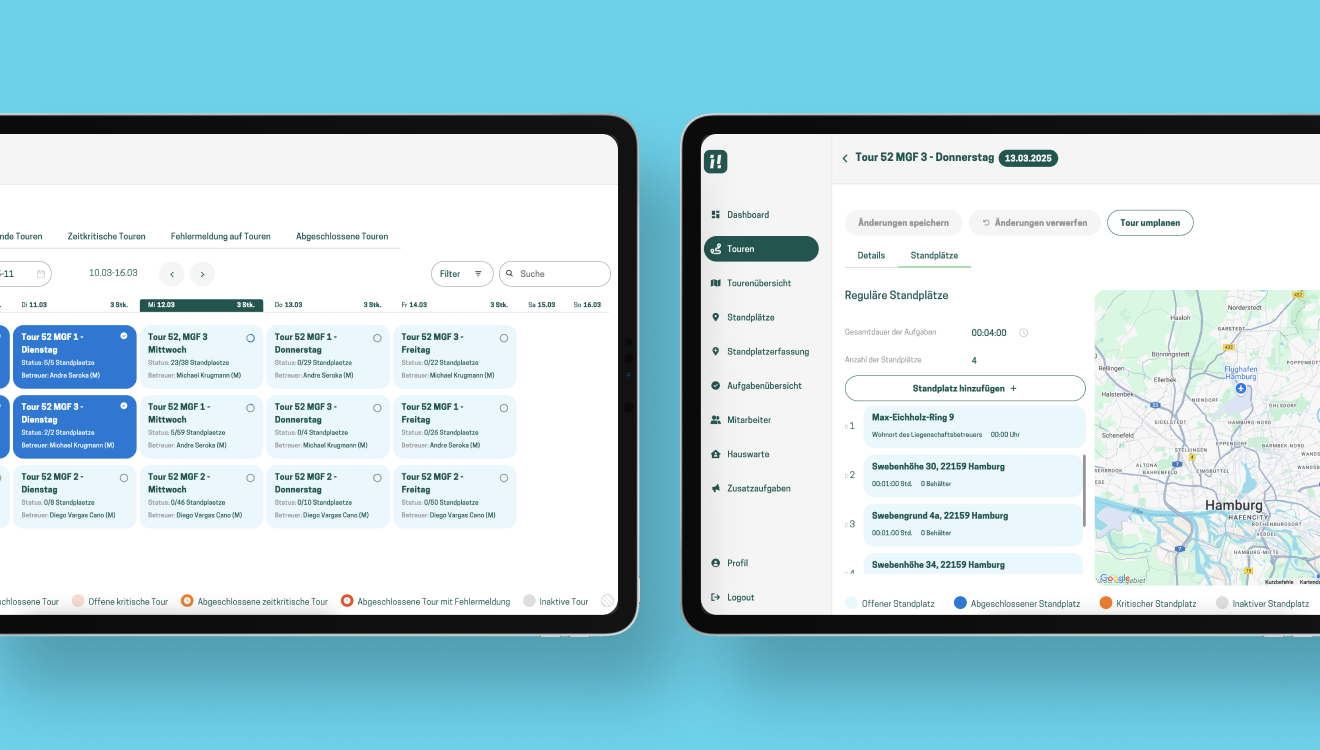

Efficient route planning

The back office system takes over the strategic control of waste disposal logistics. Intelligent algorithms optimize tours according to location, capacity and time window. This reduces empty runs and distributes resources evenly.