Increased efficiency

The new platform reduces the calibration effort by over 30%. Automated measurements and process steps enable significantly faster execution and minimize manual intervention.

TechnipFMC, a global leader in the energy industry, was faced with the task of modernizing the calibration process of its tank truck chambers. The existing software was outdated, labor-intensive and error-prone. The aim was to find a solution that combined precision and ease of use - and met the industry's high safety and efficiency requirements. P&M developed a customized platform that integrates software and hardware components and automates the entire calibration process. The use of modern technologies resulted in a system that raises speed, accuracy and user-friendliness to a new level.

The new platform reduces the calibration effort by over 30%. Automated measurements and process steps enable significantly faster execution and minimize manual intervention.

A precise measuring system and stable system architecture ensure reproducible results that meet high industrial standards. This means that every calibration process is documented in a traceable and reliable manner.

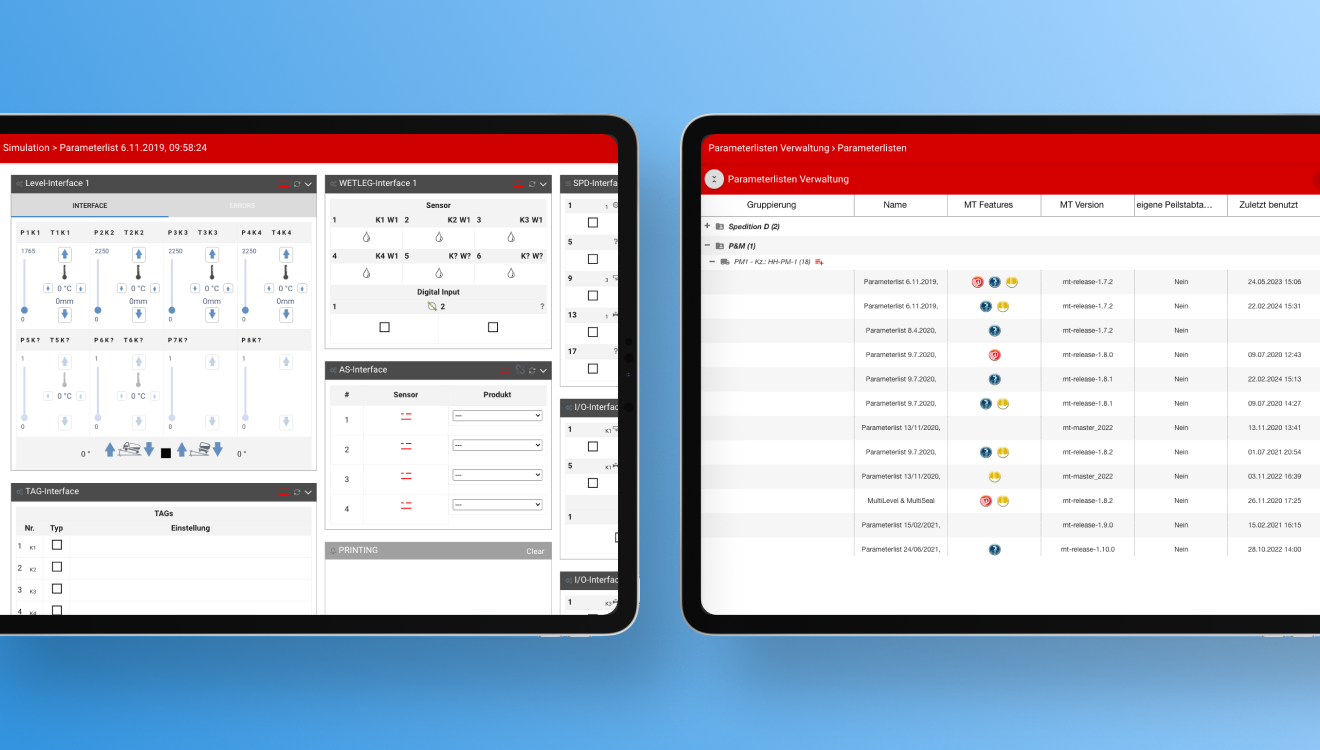

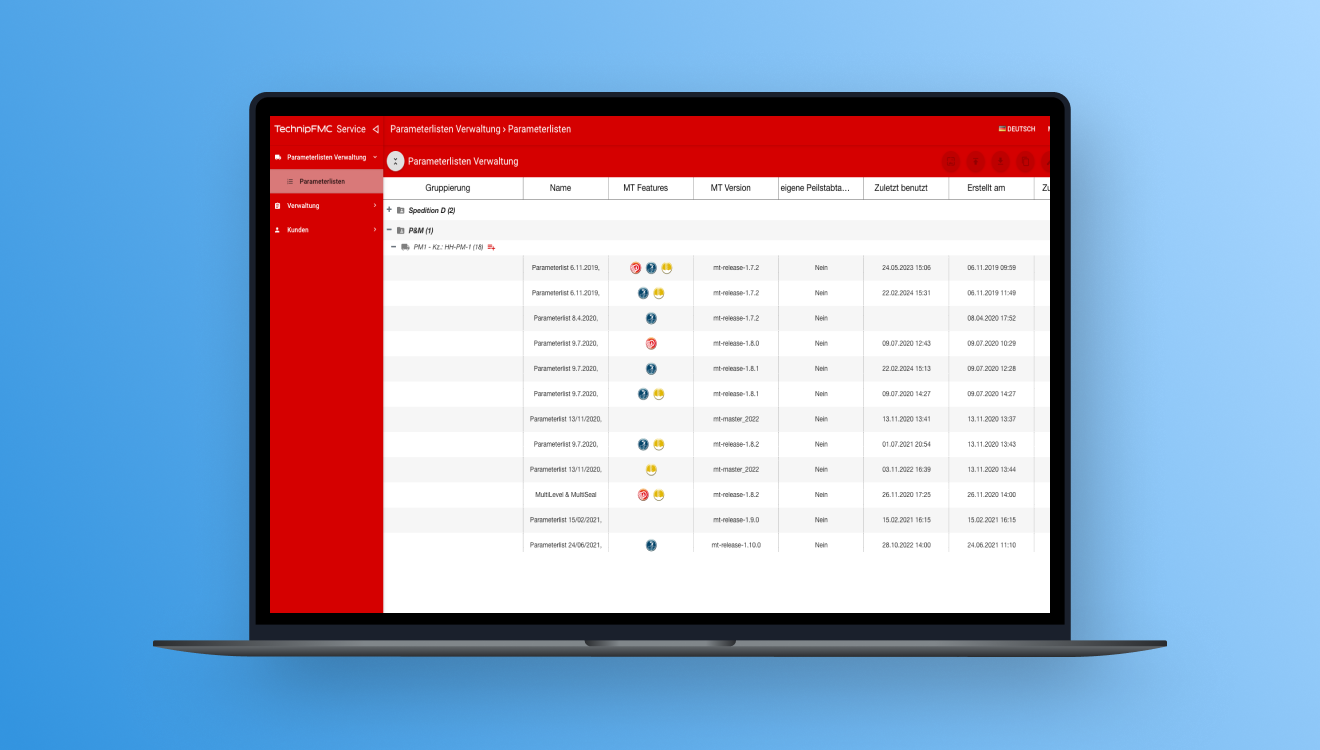

An intuitive, display-based interface guides users step by step through the process. This cuts training times and reduces operating errors - especially in mobile use.

Challenges

The project began with the optimization of a complex system with up to 24 tank chambers. The project implementation required:

P&M supported TechnipFMC from the initial analysis through to the operational rollout.

The focus was on precision, transparency and smooth integration into existing processes.

In six clearly defined phases, a scalable solution was created that combines efficiency and technical excellence.

Joint inventory of existing processes and technical requirements - the basis for a clear understanding of the process.

Development of a modular platform architecture that combines software and hardware components in a secure and scalable way.

Construction of a functional prototype to simulate real measurement series and to check system stability.

Implementation of the solution in C++ and Node.js, with an Angular interface and Three.js visualization for intuitive operation.

Carrying out extensive field tests to ensure accuracy, performance and safety under real-life conditions.

Introduction of the solution into operations, including training of the TechnipFMC team - for smooth, autonomous use.

Result

The solution completely replaces the previous platform and sets new standards in efficiency and process reliability.

Automated processes significantly reduce the time and resources required. At the same time, the architecture enables future extensions and integration of additional systems.

The result is a system that not only meets today's requirements, but also anticipates the technological progress of tomorrow.